Optical Comparer

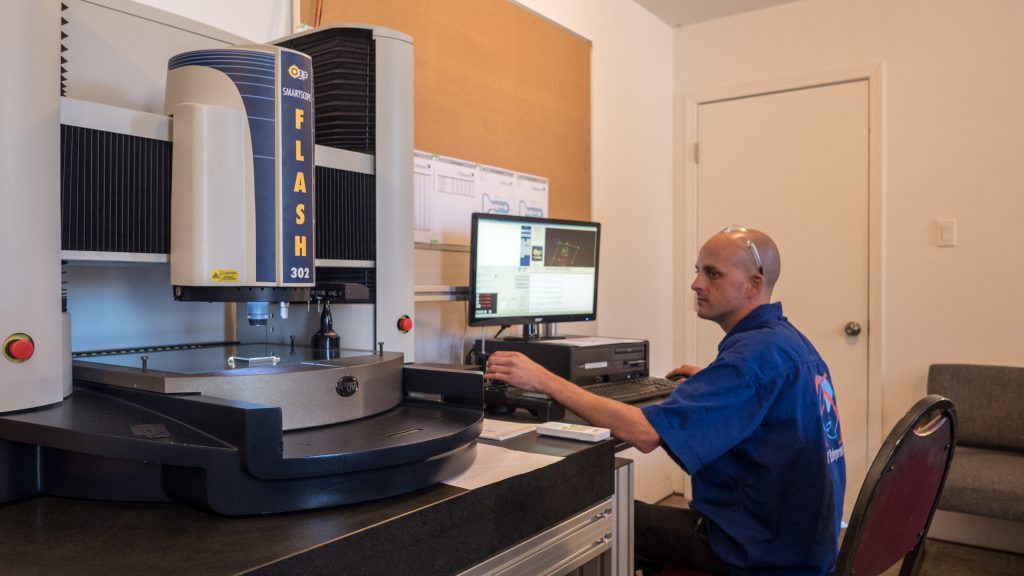

Inspection reports are available in many different forms (see sample reports). Inspections are performed on an OGP Smartscope CMM that has Video, Laser, and Touch Probe capabilities.

GD&T dimensions are reported in picture format for ease of determining surface profile conformance, and location to datum features conformance.

QUALITY OBJECTIVE

Quality Objective

Our quality objective is to meet or exceed the requirements of your drawings, and technical specifications, and expectations.

FACILITY

inspection room

Our facility is certified to Standard ISO 13485 by an accredited certification agency.

CB Enterprises has a state of the art dedicated, temperature controlled inspection room that houses all final inspection equipment, and parts.